End-Suction Centrifugal Pumps (DIN 24255 Standard)

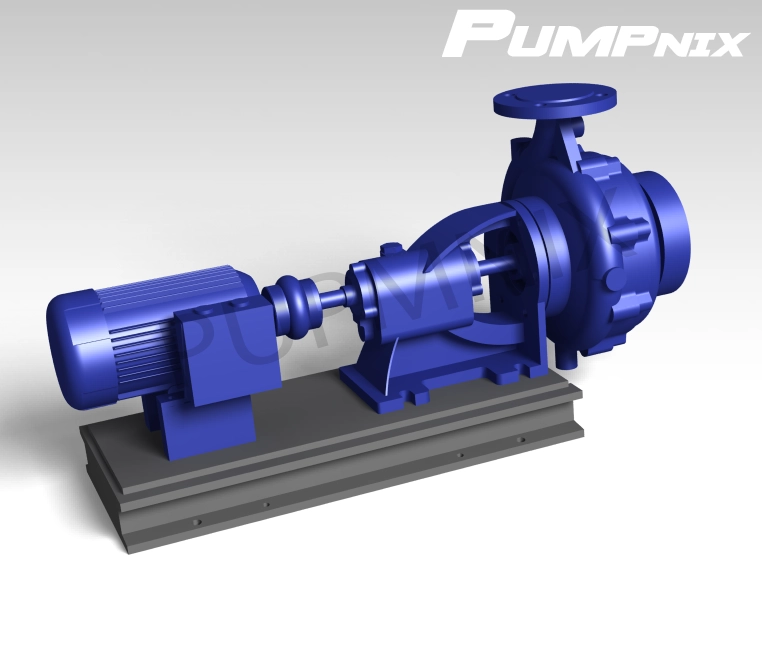

ETA ALT Pump Series

Standard Horizontal End-Suction Centrifugal Pumps

ETA ALT (ETA C & D) Series

As part of the complete technology transfer package, Pumpnix offers the ETA ALT series – a proven range of horizontal end-suction centrifugal pumps engineered in accordance with DIN 24255 standards.

This series covers a wide performance range up to 1,800 m³/h and heads of up to 140 m, with both single-stage and two-stage configurations available (sizes 100-50/2 and 125-50/2 as two-stage models). The pumps feature overhung radial-flow impellers with balance holes, renewable wear rings, and shaft-protecting sleeves to ensure extended service life and hydraulic stability

Installation Plan and Engineering Know-How

As part of the complete technology transfer package, Pumpnix provides a detailed Installation Plan for every pump type. These technical documents are not merely drawings, but essential engineering references that define:

Precise dimensions of suction and discharge flanges

Baseplate layout and anchor bolt positioning

Maintenance clearance and coupling alignment tolerances

Maximum allowable forces and moments on the nozzles, based on ISO 5199 / ISO 9905 guidelines

These drawings ensure accurate pump mounting, long-term reliability, and mechanical integrity during operation.

With its deep engineering expertise and hands-on manufacturing experience, Pumpnix empowers your technical team to fully understand and implement these standards.

We don’t just provide the drawings — we transfer the knowledge behind them, train your engineering staff, and help you build a structured technical archive for every pump series in your production line

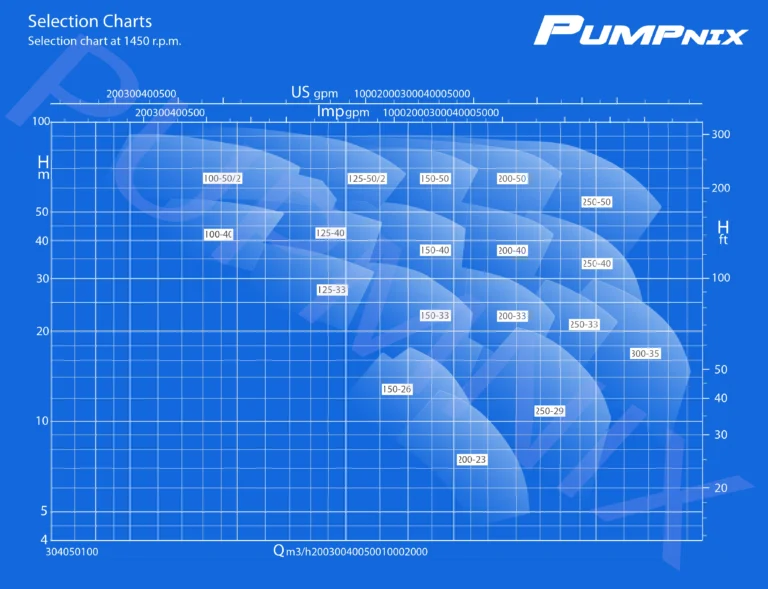

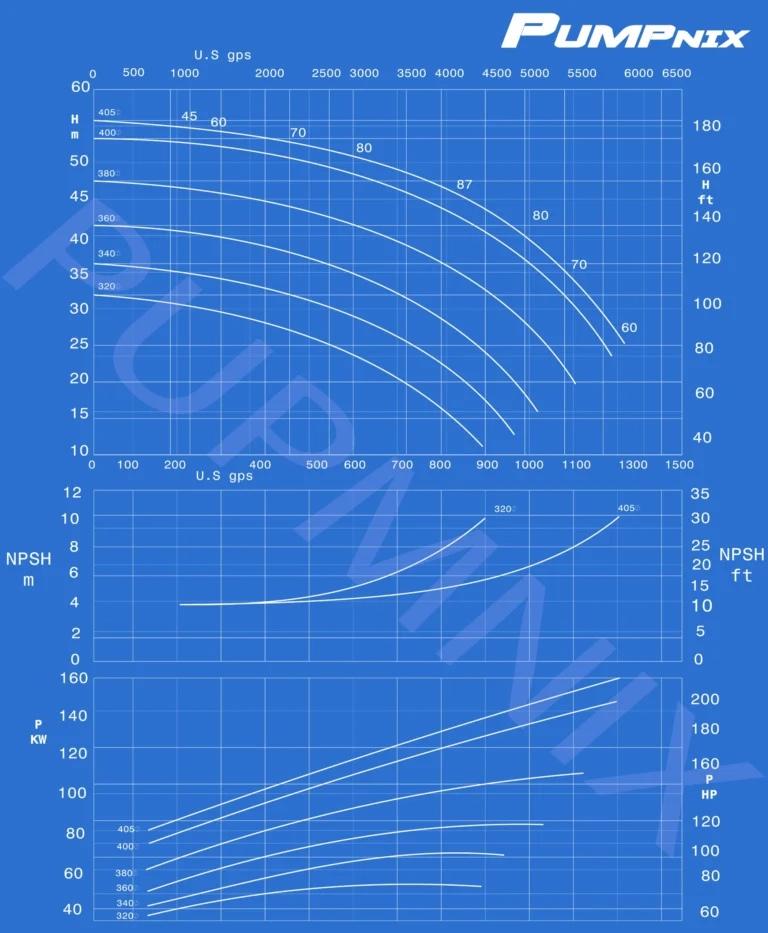

Hydraulic Performance Charts and Technical Documentation

As part of the complete technology transfer package, Pumpnix delivers precise hydraulic performance charts (coverage charts) for the ETA ALT series. These charts define the operating envelope of each pump type across the three standard motor speeds (2900 / 1450 / 960 RPM) and are further detailed by impeller trim diameters, ensuring accurate matching with project-specific operating conditions.

The diagrams include key hydraulic parameters such as head, flow rate (Q), shaft power, motor performance, and NPSH requirements.

In addition, detailed datasheets, dimensional specifications, and component-level parts lists are prepared for every ETA ALT model.

These engineering documents are essential tools during the pump factory setup phase, supporting accurate product selection, production planning, and sales engineering.

At Pumpnix, we not only provide these documents — we integrate them into your engineering department, train your technical and sales teams, and help establish a structured engineering archive for the ETA ALT family.

The sample diagrams and datasheets shown above represent real technical documentation from the ETA ALT series, serving as a foundation for both learning and implementation.

Our Products

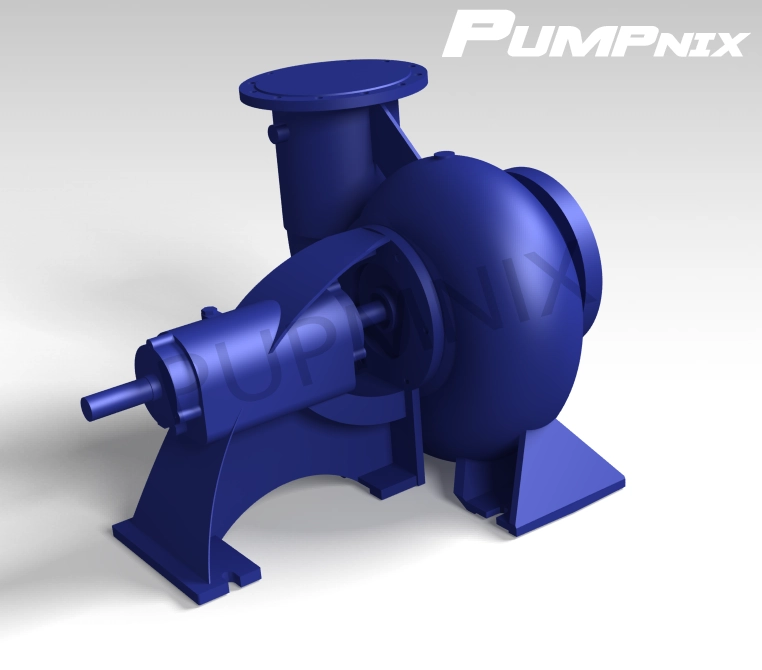

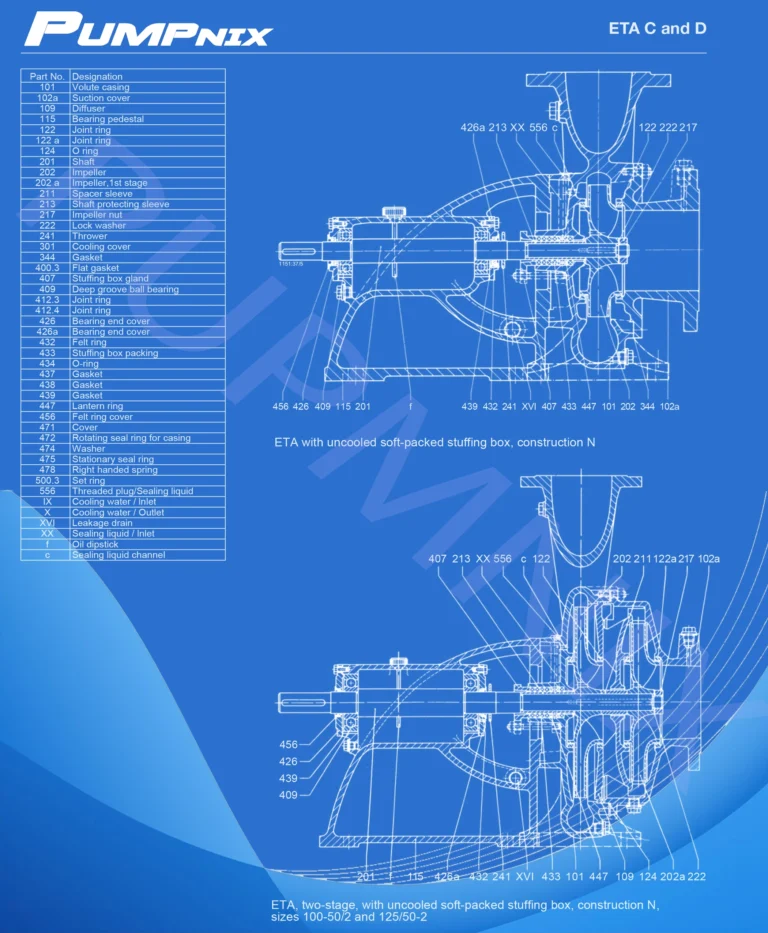

Sectional Design and Internal Function of the ETA ALT Pump

Explore All Collections

The ETA ALT pump is engineered with an axial suction nozzle and a radial discharge outlet. The fluid enters through the suction side, is accelerated by the radial-flow impeller, and its kinetic energy is transformed into pressure energy within the volute casing. A clearance gap and renewable wear rings minimize backflow losses. The pump shaft passes through the casing cover and is sealed by either a stuffing box or mechanical seal, while being supported by oil- or grease-lubricated deep groove ball bearings within the bearing bracket

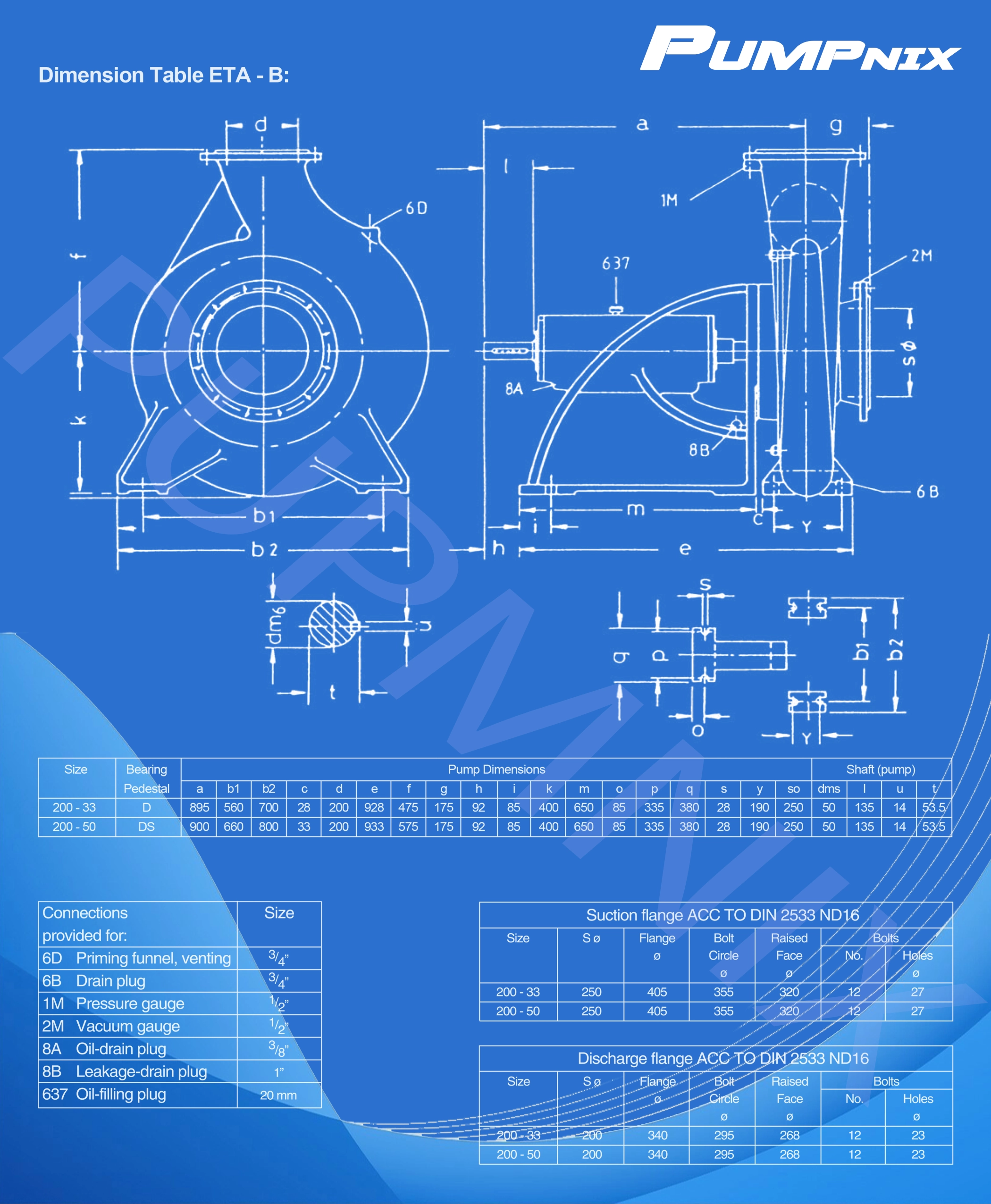

Exploded Views and Dimensional Drawings of the ETA ALT Pump

Component-Level Understanding

For the ETA ALT series, Pumpnix provides detailed exploded views and dimensional drawings that clearly illustrate every component of the pump assembly. These diagrams allow engineers to visualize the complete structure, including volute casing, impellers, shaft, bearings, seals, and all auxiliary parts.

Such documentation supports accurate manufacturing, assembly training, and service planning, ensuring that your team gains hands-on knowledge of how each part interacts within the pump system. The dimensional specifications also guarantee precise casting, machining, and alignment during production.

As part of the technology transfer package, Pumpnix delivers these exploded diagrams along with 3D CAD models, parts lists, and engineering documentation — creating a comprehensive reference archive for your engineering department and empowering your staff to independently manage production, assembly, and maintenance of the ETA ALT pump range.

Dimensional Drawings of the ETA ALT Pump

Precision for Manufacturing and Installation

For the ETA ALT series, Pumpnix provides fully detailed dimensional drawings that specify every critical measurement of the pump and its components. These drawings cover overall pump dimensions, nozzle sizes and orientations, shaft details, and bearing bracket arrangements, enabling precise integration into plant layouts and foundation designs.

The availability of these drawings ensures accuracy during casting and machining, proper alignment during assembly, and smooth interfacing with piping and motor drives.

As part of the technology transfer package, these dimensional drawings are delivered together with 3D CAD models, manufacturing tolerances, and installation guidelines, providing your engineering team with a complete framework for both production planning and on-site implementation of the ETA ALT pump family.